Enhancements to the centuries-old digital autocollimator, a fundamental instrument for angular alignment and optical metrology, promise to meet the challenges of the modern high-technology photonics world.

Originally designed to measure angles, optical alignment, straightness, flatness, and parallelism, using a technique utilized in optical metrology for over a century, a digital autocollimator projects a collimated beam through an objective lens and captures the back-reflection from a mirror using the same objective lens, from which the term “autocollimation” is derived. The reflected image is then focused onto a charge-coupled device (CCD) detector. Through image processing and algorithms, this detector calculates the deviation between the initially projected beam and the incoming angular deviation of the reflected beam.

Measuring with an electronic autocollimator is a fast, easy, and highly accurate method and often is the most cost-effective choice. Widely employed in workshops, tool rooms, inspection departments, and quality control laboratories worldwide, these sensitive instruments excel at measuring minute angular displacements, squareness, twist, and parallelism.

However, the modern high-tech industry presents unique challenges due to its intricate nature, integrating various technologies, such as lasers, vision systems, computers, electronics, augmented and virtual reality (AR/VR) software, LiDAR, and more. New high-tech autocollimators aim to address the additional complexity by providing a comprehensive solution with multiple measurement capabilities integrated into a user-friendly electronic instrument.

With this ‘Swiss army-knife’ inspired approach, the autocollimator has re-emerged as a leader in performance characterization for many photonics-related instruments. These applications span from AR/VR goggles and 3D LiDARs to satellite alignment and the inter-alignment of multiple optical elements combined with electronic sensors and lasers. The capabilities of this new instrument are extensive, encompassing optical and laser alignment, illuminated target projection, non-contact mechanical measurements in a plane perpendicular to its line of sight, laser characterization, laser and LiDAR characterization, power measurement, and distribution, among many others.

Autocollimator upgrades

These enhancements have made the devices more versatile and compatible with the demands of photonics. Here are some upgrades recently developed and implemented into Duma Optronics’ autocollimators (see Fig. 1):

Enhanced imaging sensor sensitivity. Upgraded sensors offer a large working area with extreme pixel count (up to 47 Mpixels) and deliver beam profiling capability from deep UV to IR. This functionality is crucial in photonics applications where precision is essential, such as aligning optical components in high-capacity optical communication systems and analyzing incoming laser beams to their aperture.

Multi-axis measurements. The device allows for simultaneous measurement of multiple angles in various axes, which is especially useful in the photonics field, including optical setups that require complex multi-axis alignments and multi-beam laser analysis, such as LiDAR systems.

Digital outputs and advanced GUI for improved data logging and analysis. Outputs via USB 3.0 and supported by controlled DLL makes it easier to interface with external computers and other digital control systems commonly used in photonics applications.

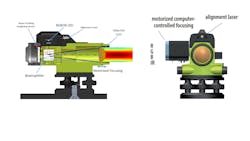

Motorized micro-alignment and non-contact measurements. Combining the functionality of an autocollimator with accurate motorized focusing and a few seconds of line-of-sight retention enables the collection of images from finite distances of optical or mechanical elements. This capability is beneficial for alignment and remote, non-contact size measurement with an accuracy of a few microns. A special feature allows projecting of imaginary objects to enable the alignment of various types of cameras.

Illumination. The built-in multi-wavelength illumination can be switched to provide perfectly aligned cross sources in RGB, or RG-IR for the analysis of optical-coated lenses (see Fig. 2).

Improved data logging. Enables the collection of large datasets for analysis, which is beneficial in photonics research where precise alignment and stability of optical components are critical.

Reduced noise and interference. Ensures more accurate measurements, particularly in sensitive photonics experiments.

Wavelength compensation. The focusing feature enables wavelength compensation as a function of the illumination source, which is also advantageous for applications involving multiple laser sources.

Remote control and automation. Enables continuous monitoring and adjustment in photonics setups.

Real-time feedback. Allows for rapid adjustments of angular deviations in optical systems, which is essential in dynamic photonics applications like laser beam steering.

Beam profiling and characterization. A crucial aspect of photonics research and development.

Compact and lightweight designs. Provide more portable and suitable systems for field applications, such as remote sensing and lidar systems.

Improved calibration methods. Enhanced techniques and software ensure the accuracy and traceability of measurements in the photonics field.

Advanced optics. Improves precision, allowing for more accurate angular measurements and reducing optical aberrations.

Autocollimator applications

Multifunctional autocollimators serve a wide range of applications in optical alignment, laser beam analysis, inter-alignment between optical elements, lasers, and mechanical components, as well as the analysis of complex photonic assemblies.

1. AR/VR goggle testing and verification:

- Lens alignment measurement

- Focus and virtual object distance verification

2. Multi-laser LiDAR system testing and verification:

- Laser emitter alignment

- Collimation check

3. Optical element testing and alignment

- Optical component collimation

- Centration verification

4. Fiber-optic laser alignment and collimation:

- Fiber coupling alignment

- Fiber output collimation

5. High- and low-power laser accuracy verification:

- Power stability and beam quality monitoring

- Alignment and collimation for high-power lasers

6. Laser resonator alignment: cavity mirror alignment for applications like laser marking and laser engraving

7. Laser gyroscope accuracy: angular deviations measurement

8. Laser-based metrology: beam alignment verification

9. Laser diode characterization: beam property, beam divergence, collimation, and other beam parameter analysis

10. Laser spectroscopy: beam alignment with the target samples or detectors

11. Laser spectroscopy techniques: beam alignment and control

12. Medical laser systems: laser system alignment and calibration

With many enhancements, multi-task and multi-sensor electronic autocollimators have evolved to meet the demands of the photonics field, with improvements in sensitivity, data management, automation, and compatibility with various light sources. These upgrades have made electronic autocollimators valuable tools for aligning and characterizing optical systems in photonics applications, ensuring precision and reliability in a broad range of research and industry settings.

Further, the new electronic autocollimators have a wide range of applications across various industries and scientific disciplines, wherever accurate angle measurements and alignment are essential. Their high precision and reliability make them valuable tools for quality control, research, and manufacturing processes.